Insulated Windows

Save energy and reduce costs with modern innovation

Solar radiation

Poorly designed windows can leave homes vulnerable to large entry of solar ultra-violet and infra-red rays. This can wear materials and objects that receive regular exposure. In warm climates the radiation can also be an undesirable source of heat.

With expertise in these potential pitfalls and designing energy-efficient windows, at Neuffer all window profiles are German high-quality and custom designed with maximum insulation in mind.

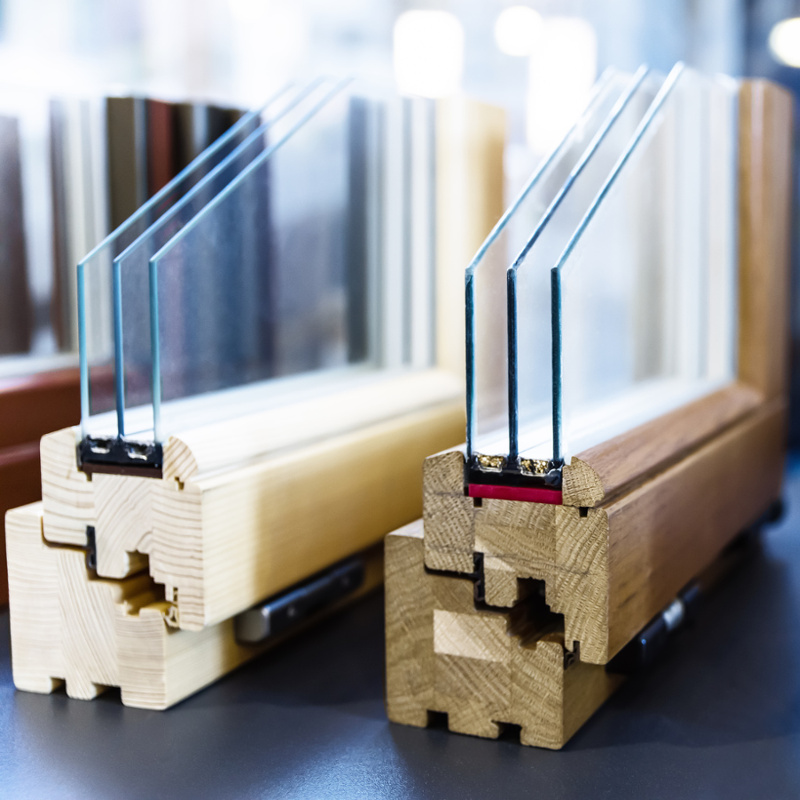

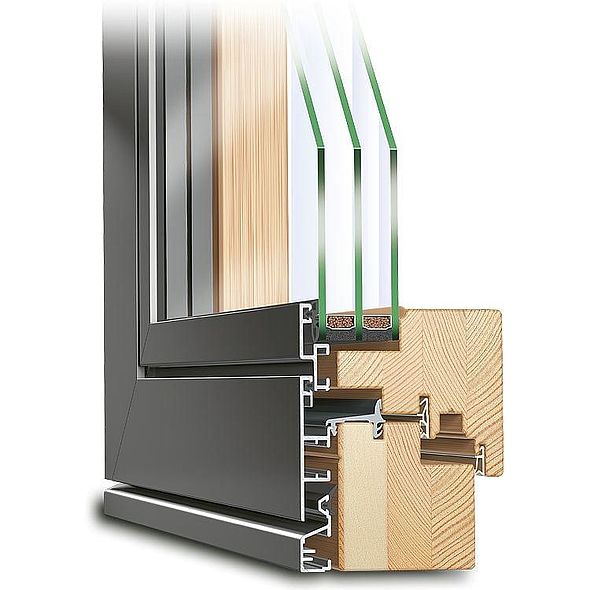

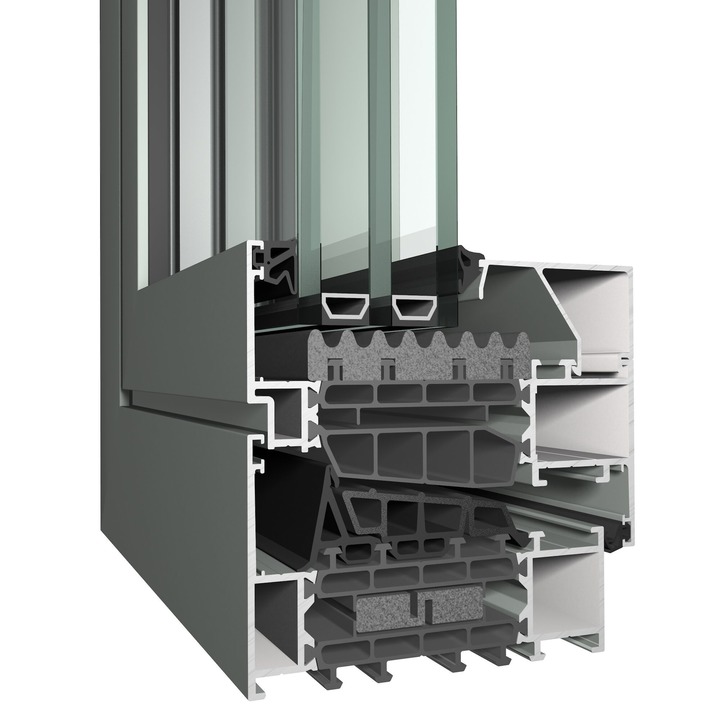

When considering the term insulation, fiberglass used in roofs or foam may be more likely to spring to mind than windows. Insulation, however, is a key element engineered into modern high-quality windows available at Neuffer.

The impact is evident too –think of the retention of heat when hot coffee is contained in a thermos rather than a standard mug, for example. The difference between regular and insulated glass windows is similar. In the case of buildings, however, this can lead to large differences in utility bill savings, a reduced carbon footprint and superior solar protection.

How are energy efficiency and windows related?

As the openings in buildings, up to 30% of a building's energy can be lost through windows. Inefficient windows can therefore lead to the following issues:

Conduction

Glass which has not been specifically designed with insulation in mind can be quite a thermally inefficient material. Conduction, the process by which heat moves from hot to cold due to temperature difference, can therefore occur. This can lead to heat loss in winter or cold climates and unwanted entry of warmth in summer or hot climates.

Air drafts

During hot weather or in warm climates worn seals or gaps between the window sash, its frame and the wall can cause unwanted warmth to enter and cold air to escape. The opposite then applies when it’s cold outside – warm air escapes and cold drafts can blow in. Whether it's hot or cold outside, comfortable interior temperatures can therefore become destabilised, and heating or ventilation bills often increase as a result.